Services

CoatMe provides these services to clients all over the world, please see the description for the right services for your needs.

We currently offer the following coating services:

Ultra-violet cured coatings can be applied over ink printed on wood and dried by exposure to UV radiation. UV coatings can be formulated up to 100% solids so that they have no volatile component that contributes to pollution. This high solids level also allows for the coating to be applied in very thin films. UV coatings can be formulated to a wide variety of gloss ranges.

Similar to the UV Coating but with tinted elements to the coating. Use for both indoor and outdoor uses, the applications are used for protection, safety, and aesthetics.

A process developed to give lightness, durability, and clear coat finish to panels that need to sustain wear, environmental elements, and add visual appeal to the finished product.

A process for producing high-gloss surfaces on at least one portion of a substrate area, where the steps comprise: a) applying a layer made of a melt to at least one portion of the substrate area; b) polishing of the applied layer of melt; c) applying at least one lacquer layer to the polished layer of melt by means of a curtain-coating process; d) hardening the layer structure applied

Different wood grains and patterns would need this type of coating to preserve the design and look of the wood panel.

Coating developed to withstand above normal wear to have the panels last longer. Ideal for flooring and outdoor applications.

Specialized coating materials that can withstand different levels of fire and/or heat. This is applicable in building materials and specfic purpose panels that are going to be subjected to heat, flames, or fire for a set amount of time.

PUR (polyurethane) glue can uniquely be applied thinner than other adhesives to achieve a high quality, smooth finish.

~ Acrylic High Gloss Laminating

A process which provides a perfectly flat mirror like gloss surface that is far superior to paints, finishes and laminates. We have the ability to provides deep high gloss solid colors without “orange-peel” or surface imperfections.

The result is a fantastic alternative to stenciling or staining and you can even use your computer to create watercolour effects in your photos, or do other freaky stuff to the images. If you’re into carving wood you can also use this technique to transfer your pattern directly onto the wood surface.

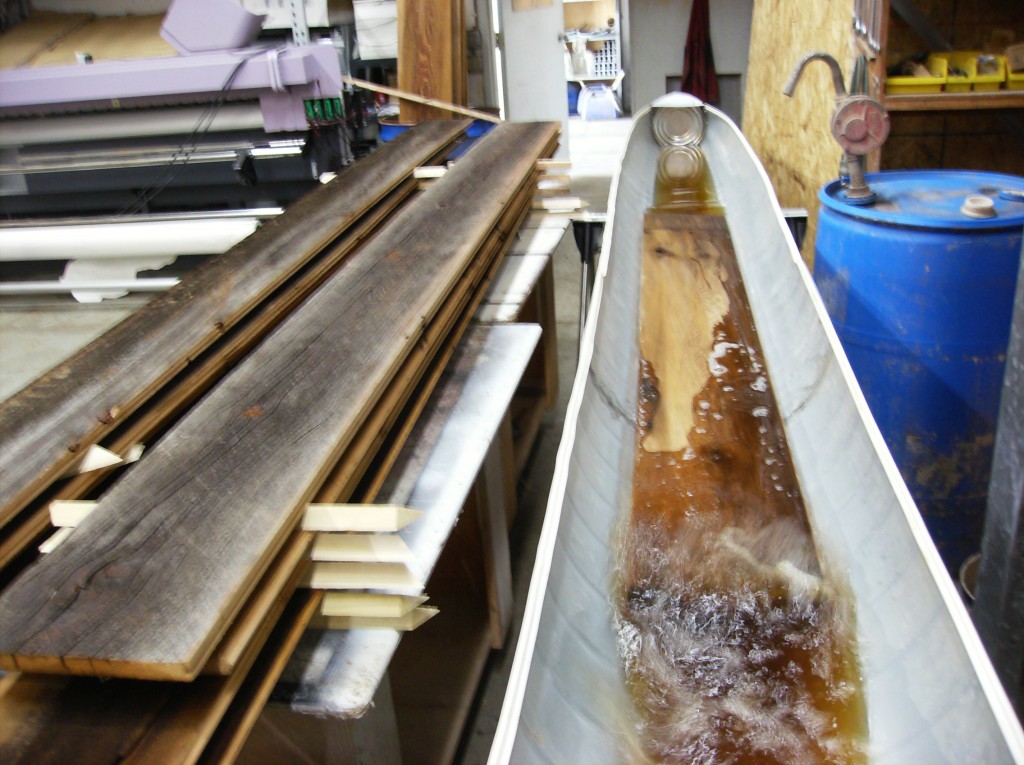

~ Skarfing

A plain scarf is simply two flat planes meeting on an angle relative to the axis of the stock being joined, and depends entirely on adhesive and/or mechanical fastening (screws, bolts, etc. ) for all strength. Hooked, keyed, and nibbed scarfs are some of the many example of interlocking scarfs, offering varying degrees of tensile and compressive strength, though most still depend on mechanical fastening to keep the joint closed.

When the joint is glued together, the tapers are slid against each other so that the two sections are no longer in line with each other. This has the effect of making the board longer. Once the glue has set, the board can be planed down to an even thickness, resulting in a longer but thinner board.

Please feel free to contact us if you should have any questions about these processes.